Complex Integration

We’re built to handle even the biggest of the big projects. Our high-tonnage transports and deep water port ensure that we can do everything from concept to delivery so you don’t have to.

KEEL is the partner that can do it all for you.

We handle the entire process—prototyping, testing, refining, producing, finishing, and delivering—ensuring that you receive precisely what you need without the hassle.

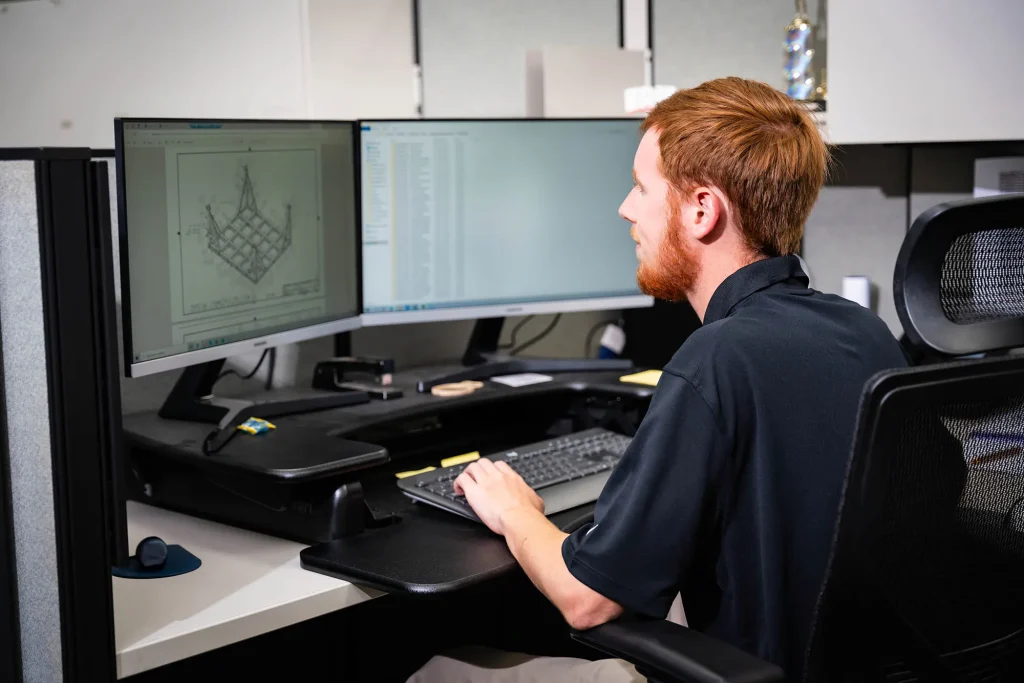

As your comprehensive partner, KEEL excels in both standalone design and large-scale manufacturing projects. Our talented assembly technicians produce a broad spectrum of fully integrated modules and complete performance tested machines and vehicles. Units are delivered with complex electrical systems, pressure tested vessels and piping, and performance validated mechanical systems. We add unparalleled value by managing every detail, so you can focus on your objectives with confidence.

What We Do

KEEL provides complete painting and coating services for various metals, including zinc-rich primer, epoxy, water-based latex, and top coats such as enamels, urethanes, and military CARC finishes. Our forced-air spray/bake booth allows for quick production of smaller, multi-coated parts, and our large facility can accommodate weldments weighing up to 100,000 pounds. Every part is inspected by our N.A.C.E.-certified paint inspector to ensure proper adhesion, consistency, and overall quality.

Our blasting services prepare all metals for painting and finishing, using media such as aluminum oxide, garnet, and glass beads. The blasting chambers can achieve commercial, industrial, and white blast finishes, ensuring a clean and primed surface for optimal coating results.

Features

- Abrasive Blasting

- Painting

- Delivery

- Chemfilm

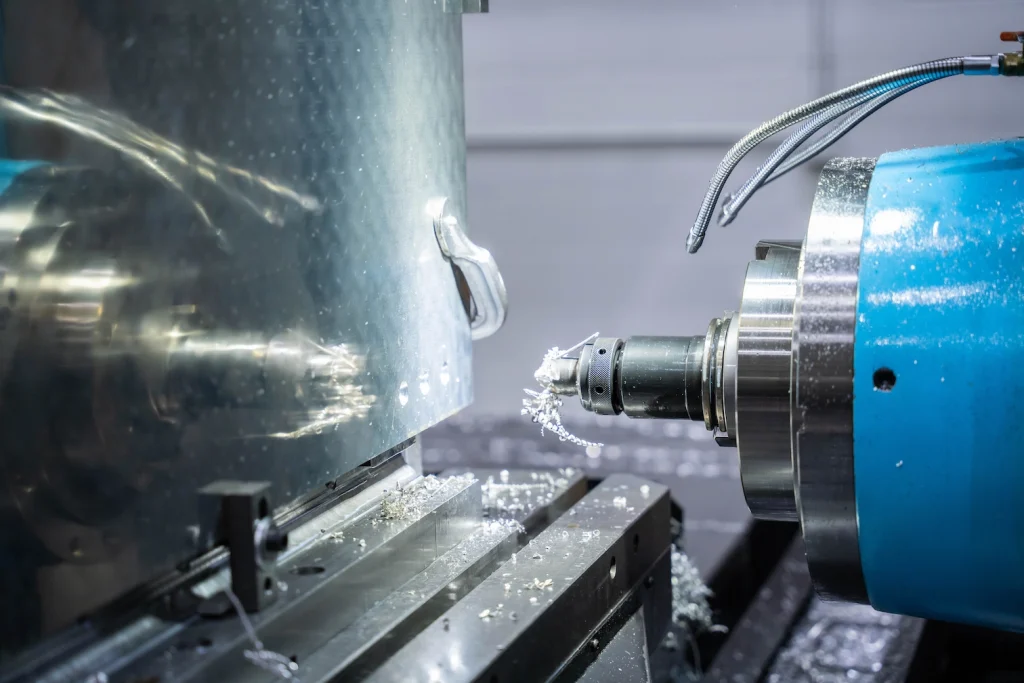

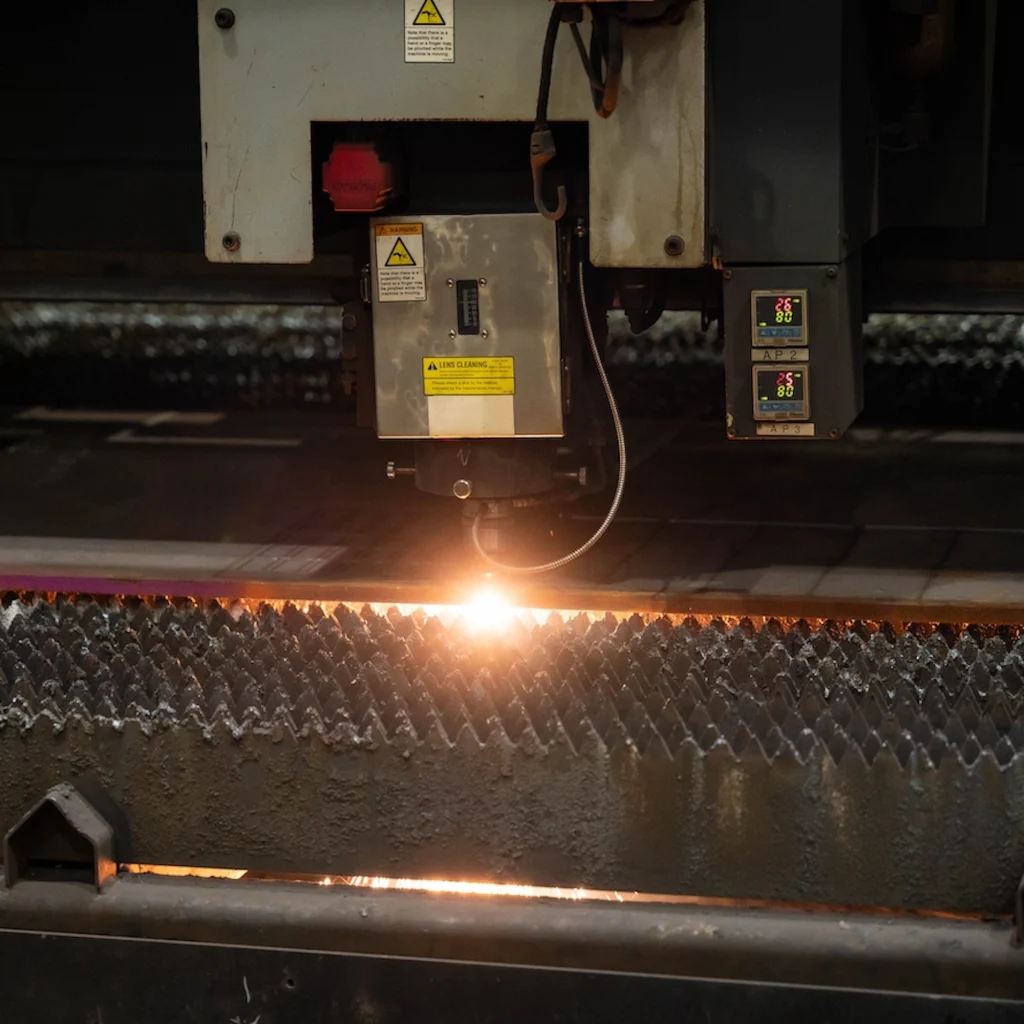

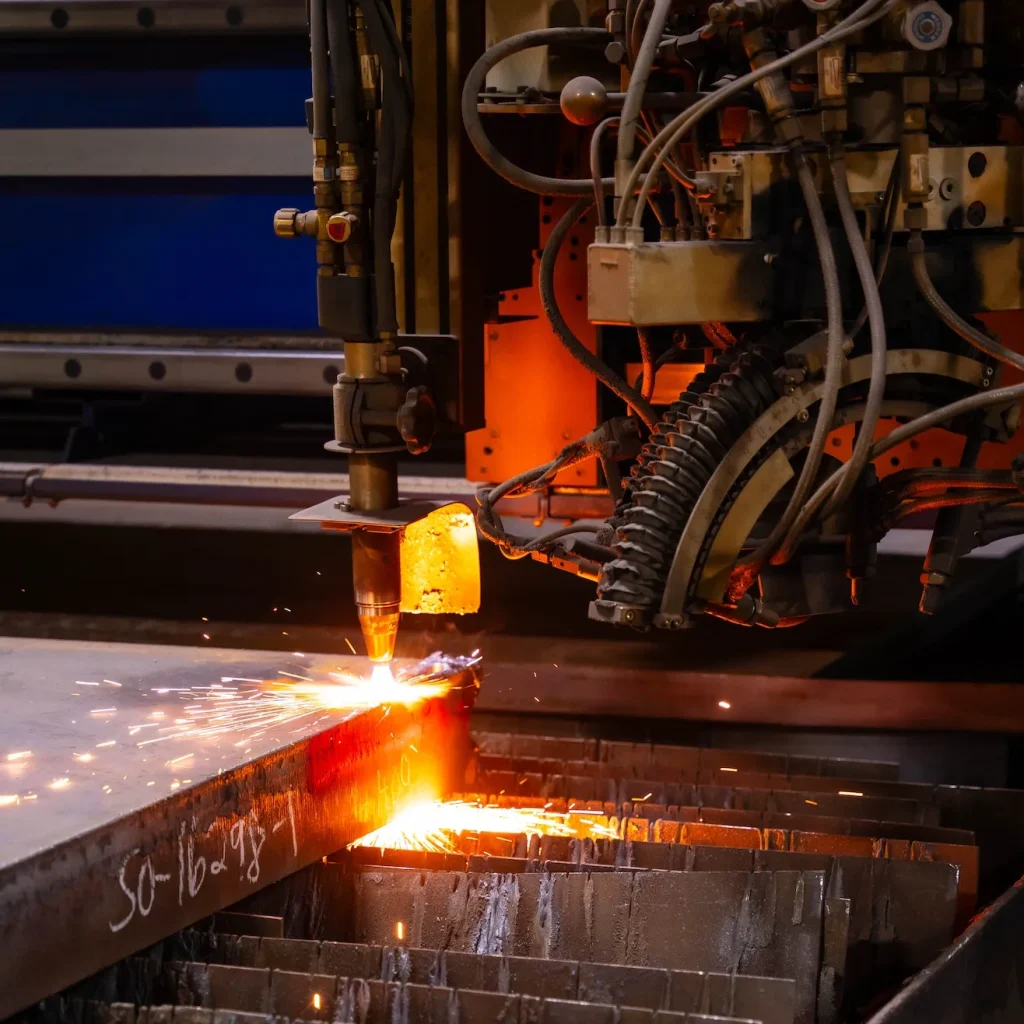

We have the ability to prototype and build for any industry that requires precision complex assembly — no project is too big or too small. We can transform existing equipment to better-than-new condition, rebuilding them so that they outperform their original configurations. Our ability to develop, design, build, machine and assemble engineering equipment means that we can provide you with the best end product, quickly, efficiently and economically.

Features

- Recondition

- Rebuild & Retool

- Standard Equipment

- Manufacturing & Assembly

We inspect every product to ensure consistency, quality and traceability. We perform a wide range of visual and dimensional testing to OEM specifications including non-destructive testing (NDT), operational testing, real time performance testing and CMM inspection. NDT is performed to nationally-recognized standards including leak testing, magnetic pulse testing and fluorescent penetrant testing.

Small or large, local or global, our onsite shipping department will deliver your product where and when you need it. And if you need us to warehouse it for just-in-time delivery, we can also do that.

Our deep water port can accommodate vessels and barges up to 380 feet long by approximately 72 feet wide with up to a fifteen (15) foot draft. We are also equipped with a 300-ton transporter, a marine railway, and an 820-ton mobile crane.

Precision Finishing

The finishing touch.

KEEL provides complete painting and coating services for various metals, including zinc-rich primer, epoxy, water-based latex, and top coats such as enamels, urethanes, and military CARC finishes. Our forced-air spray/bake booth allows for quick production of smaller, multi-coated parts, and our large facility can accommodate weldments weighing up to 100,000 pounds. Every part is inspected by our N.A.C.E.-certified paint inspector to ensure proper adhesion, consistency, and overall quality.

Our blasting services prepare all metals for painting and finishing, using media such as aluminum oxide, garnet, and glass beads. The blasting chambers can achieve commercial, industrial, and white blast finishes, ensuring a clean and primed surface for optimal coating results.

Features

Abrasive Blasting

Painting

Delivery

Chemfilm

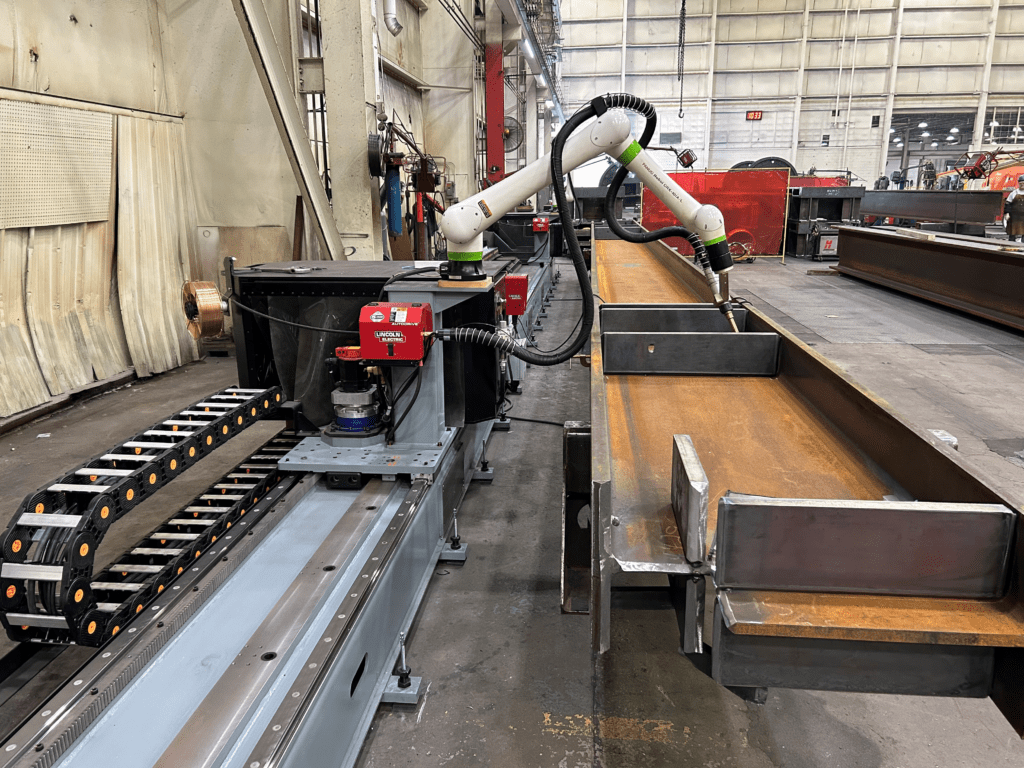

Assembly

We can rebuild it or build it from scratch.

We have the ability to prototype and build for any industry that requires precision complex assembly — no project is too big or too small. We can transform existing equipment to better-than-new condition, rebuilding them so that they outperform their original configurations. Our ability to develop, design, build, machine and assemble engineering equipment means that we can provide you with the best end product, quickly, efficiently and economically.

Features

Recondition

Rebuild & Retool

Standard Equipment

Manufacturing & Assembly

Testing

Guaranteed to be built strong.

We inspect every product to ensure consistency, quality and traceability. We perform a wide range of visual and dimensional testing to OEM specifications including non-destructive testing (NDT), operational testing, real time performance testing and CMM inspection. NDT is performed to nationally-recognized standards including leak testing, magnetic pulse testing and fluorescent penetrant testing.

Delivery

We don’t just fabricate the parts; we ensure they reach their intended destination precisely at the right time.

Small or large, local or global, our onsite shipping department will deliver your product where and when you need it. And if you need us to warehouse it for just-in-time delivery, we can also do that.

Our deep water port can accommodate vessels and barges up to 380 feet long by approximately 72 feet wide with up to a fifteen (15) foot draft. We are also equipped with a 300-ton transporter, a marine railway, and an 820-ton mobile crane.

Insights

View All

Seapower Magazine: Keel: A Purpose-Built Company

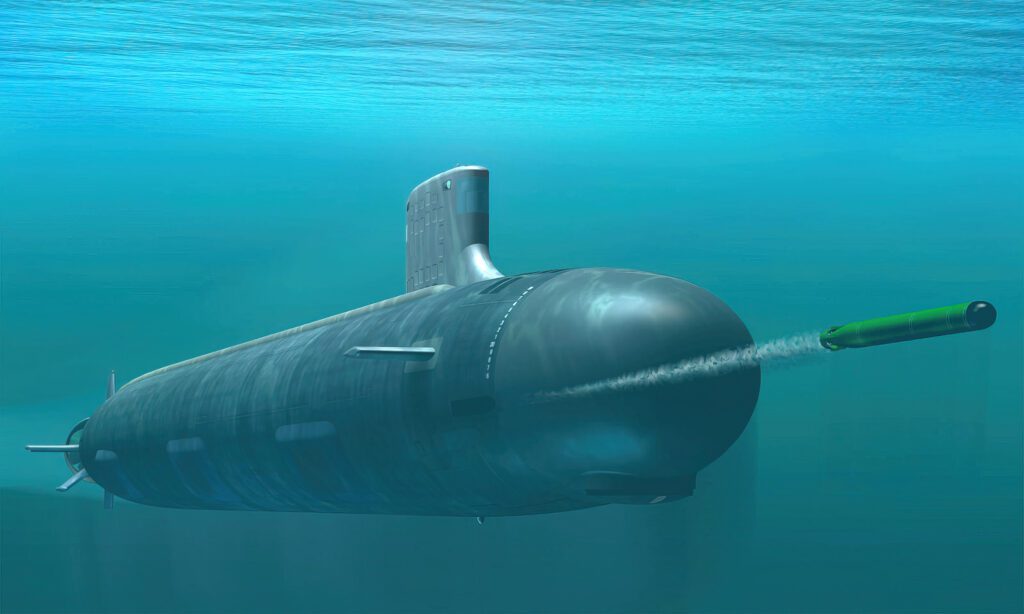

Virginia-Class Nuclear Submarine Case Study

Keel and Westinghouse Suppliers Meet with the U.S. Congress in Support of AP1000® Projects Globally

Careers

Find your next career with KEEL

We’re committed to your success through continuous professional development. We provide the tools and opportunities you need to reach your full potential. Explore our career opportunities today and build your future with us.

CAREERS

Interested in joining forces? Explore KEEL’s career opportunities