Background Information

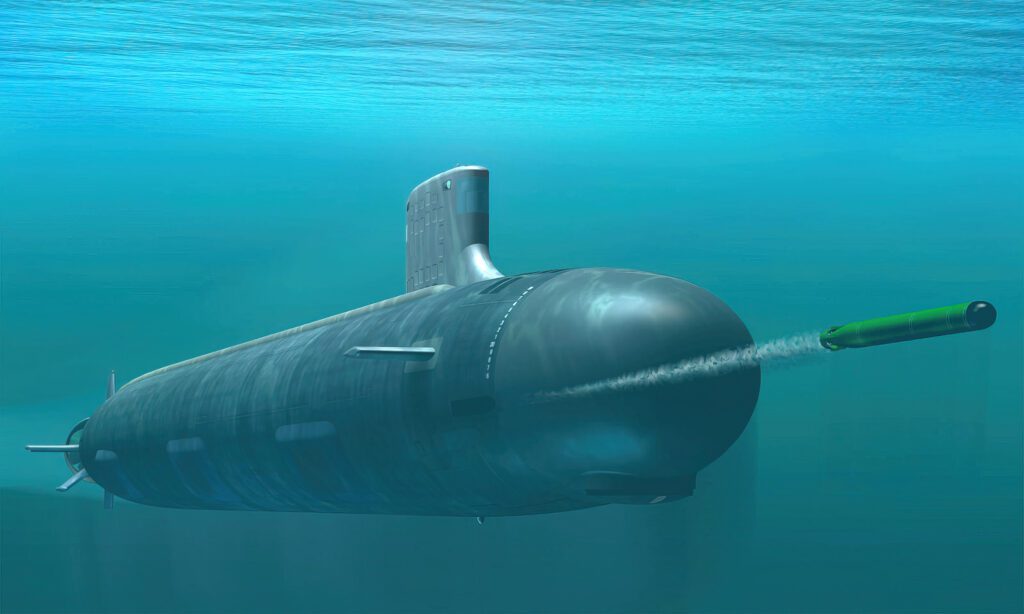

Keel was tasked to manufacture critical complex structures, including a habitation module, for the U.S. Navy’s Virginia-class nuclear-powered cruise missile fast attack submarines, which are a top priority for maintaining undersea superiority. The new submarines are intended to replace the Navy’s aging Los Angeles-class submarines and are ideally suited for a wide range of missions and intelligence gathering.

As part of the United States’ strategic nuclear deterrence, this submarine will enable the Navy to fortify its submarine force levels, which is essential for protecting our warfighters and ensuring global security.

The project, with submarine acquisition expected through 2043, poses significant challenges. However, Keel has extensive nuclear navy experience and proven defense manufacturing expertise to meet the program’s stringent demands and successfully deliver unrivaled, high-quality components on time.

Business Challenges

- A tight schedule is required for the U.S. Navy’s high-priority implementation to the fleet. The sizable structures require intense planning and large material handling equipment. Leveraging full capability and capacity is required to meet deadlines.

- The project demands an experienced manufacturing team to execute complex requirements, which include U.S. military standard (MIL-SPEC)- and Naval Sea Systems Command (NAVSEA)-specified materials and processes. Full-penetration welds require non-destructive testing (NDT) to ensure quality weld joints. Tolerances and dimensions must be confirmed before delivery to the ship integrator.

- The complex components have critical forming, machining and welding requirements. The project requires alloy welding and involves thousands of weld records. Sizable facilities are required to accommodate the magnitude of the Virginia-class structures, which must be barged to their final destination.

Approach and Solution

Following comprehensive analysis of the scope of work, the Keel team developed a detailed build sequence plan to effectively accommodate the program’s intense material planning and handling, stringent fabrication and welding requirements, and demanding delivery timeline, while also addressing the complexity and size of the structures and anticipated challenges.

In addition to complex machining of subassemblies, technologies required for this program include a 300-ton heavy transporter and complex forming and rolling, which is achieved via Keel’s industry-leading Nieland cold forming press and DAVI Mav-30 press roll equipment that can roll steel up to 7″ thick.

Keel’s team of certified welders, engineers and inspectors work closely with our customer to ensure ensure that every aspect of our work is built to meet NAVSEA’s demanding requirements. On-staff NDT technicians – led by Keel’s ASNT Level III NDT technician, experienced weld engineers and certified weld inspectors – ensure high-quality, full-penetration welds.

Value Delivered

Keel begins with precise planning to meet stringent deadlines, and the complex manufacturing process is organized by Keel’s Advanced Planning Excellence Center (APEX). All steps, from procurement to product measurement, are defined for Keel’s manufacturing staff by APEX. Each assembly step is scheduled at all Keel plants to ensure available capacity and conformance to the delivery schedule. Concurrently, Keel’s purchasing department and supplier development group work with our dependable supply partners to ensure materials are delivered on time and to specifications.

With a large staff of non-destructive technicians, Keel also has the depth and skills to ensure high-quality welded joints in the superstructure components. In addition to having the material lifting/handling equipment required for the sizable structures, our extensive nuclear navy experience and large library of NAVSEA weld procedures make Keel an industry leader for this type of highly specialized welding.

At Keel, we excel in delivering large, mission critical steel fabrications using advanced welding and construction techniques. Our expertise meets the stringent NAVSEA nuclear requirements, ensuring the safety and reliability of both surface and undersea naval platforms.

Through our well-appointed facilities, state-of-the- art equipment and highly skilled team, Keel has contributed to the construction of Virginia and Columbia-class submarines, as well as Ford- and Nimitz-class carriers.

With a commitment to precision and excellence, and proven success with complex challenges, we deliver innovative solutions that support mission-critical naval programs, keeping your projects on course from start to finish.

“The appearance of U.S. Department of Defense (DoD) visual information does not imply or constitute DoD endorsement.”