Precision Machining

With over 70 state-of-the-art CNC milling and turning centers leveraging CGTech’s Vericut software, our skilled machinists are able to deliver the most exacting tolerances.

No matter the scale of your project, Keel is equipped to meet your needs with accuracy and reliability.

Whether you require a part compact enough to fit in the palm of your hand or a massive component weighing over 100,000 pounds, Keel has the expertise and cutting-edge machinery to handle it.

We utilize CGTech’s Vericut software to simulate machining before starting any operation. This helps us detect inefficiencies, eliminate manual prove-outs, prevent tool-blocking errors, and reduce scrap.

We create solutions to solve your challenges.

What We Do

From standard components to the most intricate and complex parts, Keel has both the talent and the advanced tools necessary to transform your toughest machining challenges into practical, working realities. Whether it’s high-precision structures, complex geometries, or custom fabrication, our team excels at delivering solutions that meet the most demanding specifications, ensuring precision, reliability, and performance in every project.

Our state-of-the-art CNC mills and skilled technicians ensure that every part is crafted to your exact specifications. Many of our milling machines accommodate parts with sizes larger than 96 inches x 96 inches. One of our largest capabilities is our 5-axis double column machining center with a maximum capacity of 80 inches x 148 inches x 394 inches. While two other 5-axis machines can handle up to 52 feet long.

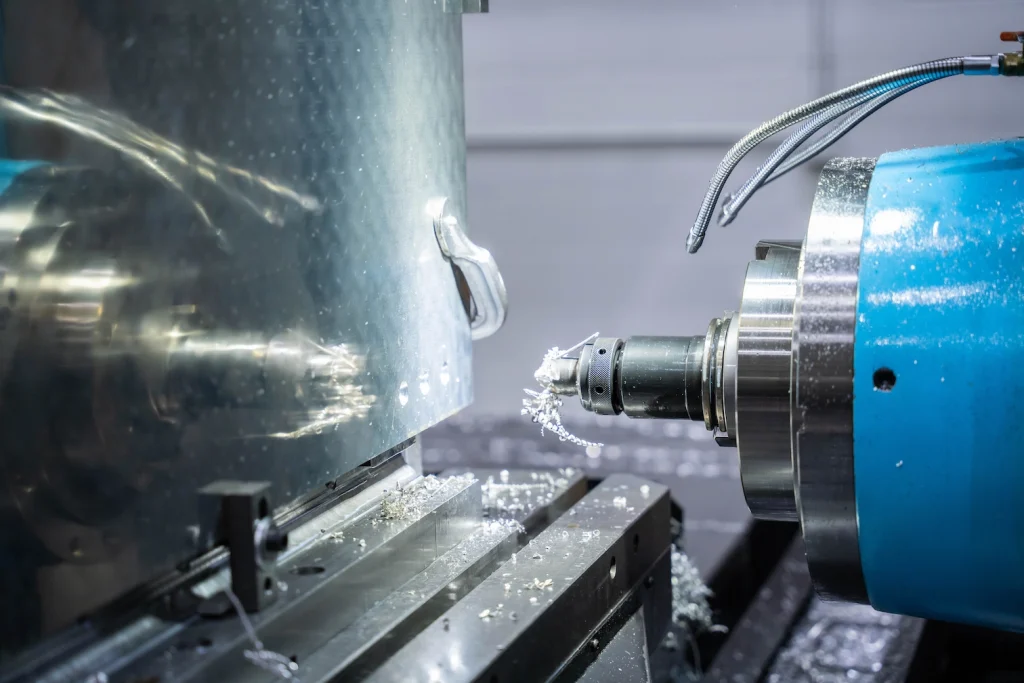

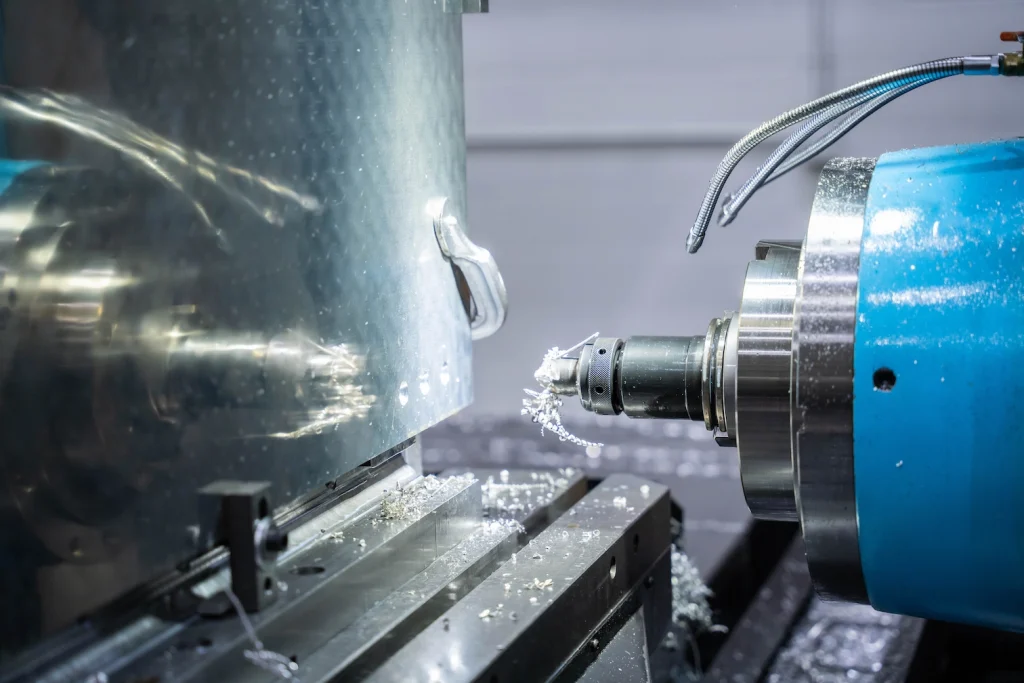

Our advanced CNC turning capabilities ensure tight tolerances, smooth finishes, and fast turnaround times. From prototypes to high-volume production, CNC turning provides the reliability and precision your project demands.

Our wide array of vertical and horizontal CNC turning centers boost capacities from 145 inches in diameter by 118 inches tall (perpendicular) to 35 inches in diameter by 120 inches long (horizontal).

We offer both horizontal and vertical grinding services. Keel is a premier source for ID/OD grinding; we can handle parts up to 15 inches in diameter and 72 inches between centers while holding precise tolerances to 0.0005 inches over the entire length of the part. Our large-diameter vertical equipment provides close-tolerance, fine-finish ID/OD grinding up to 60 inches in diameter.

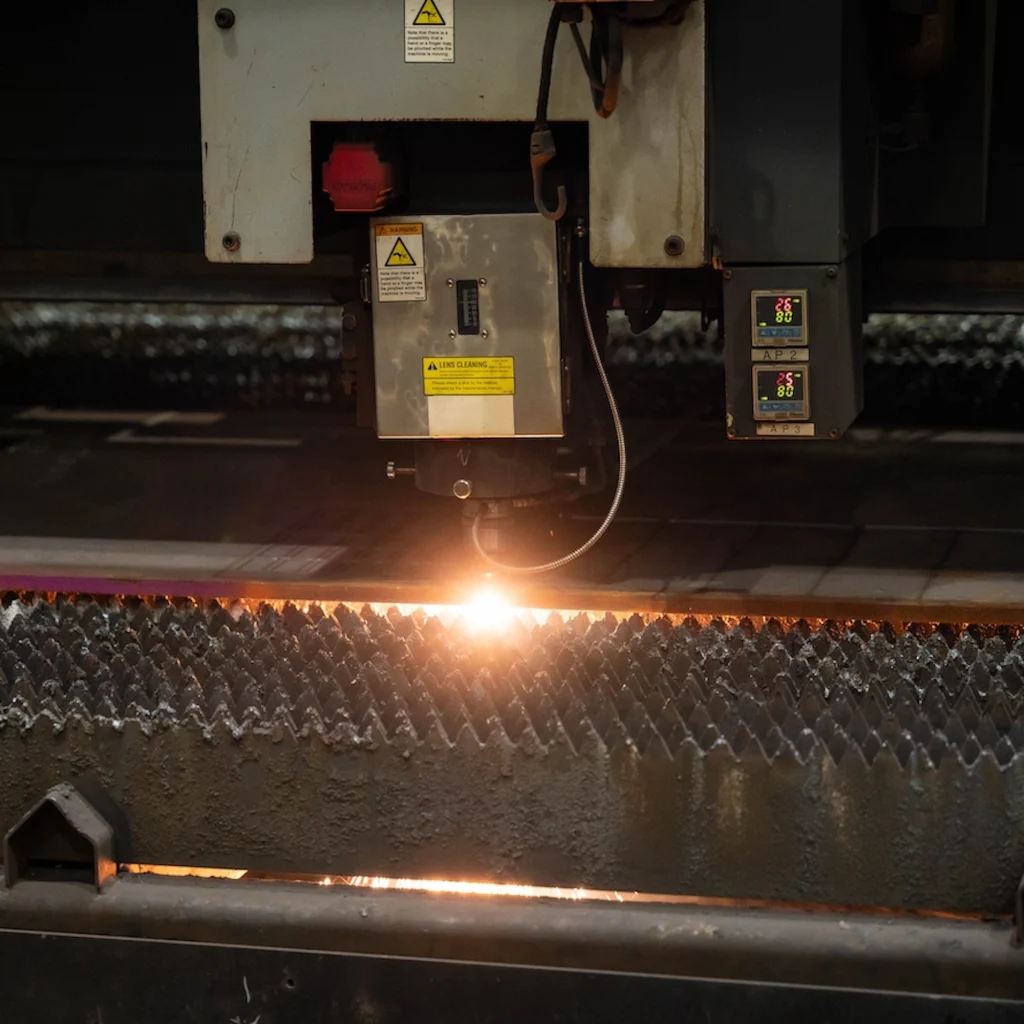

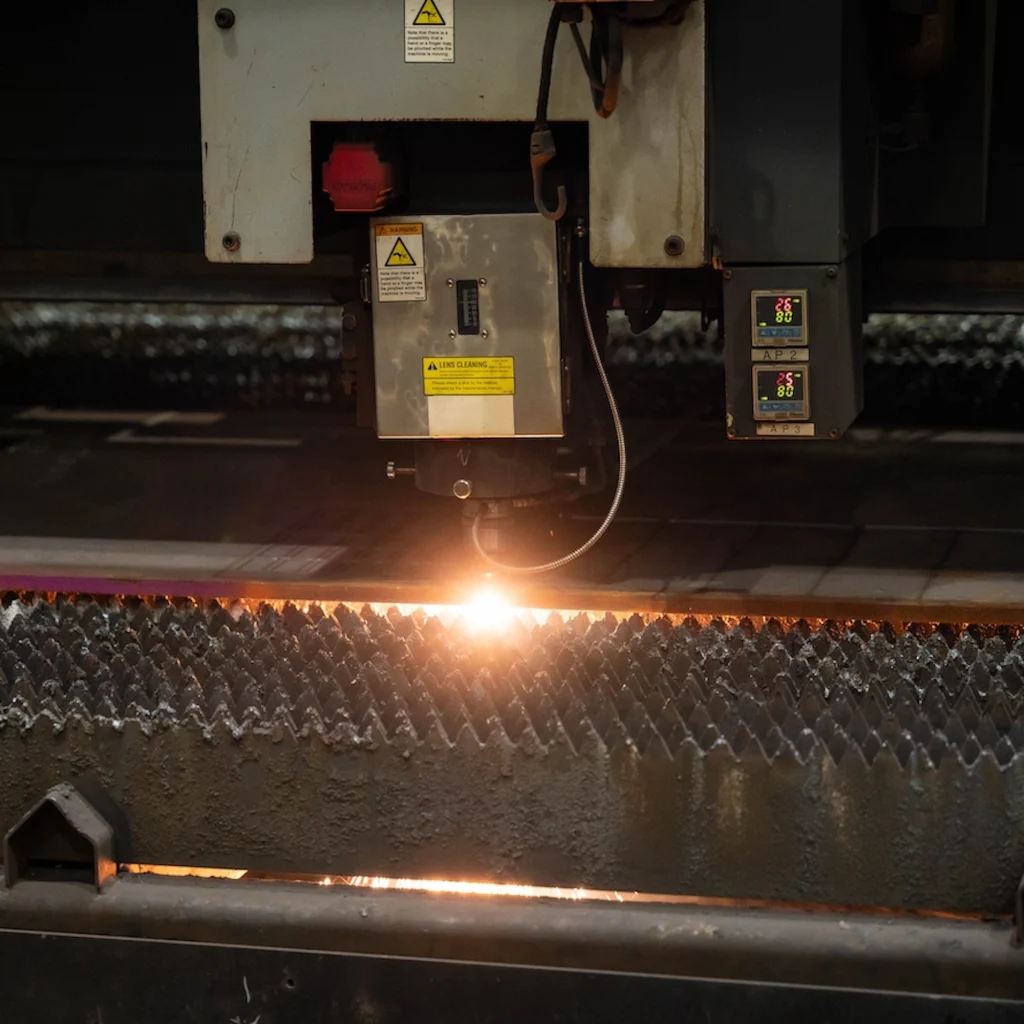

Precision only a laser can do. We have the capability to mark virtually any design onto a wide range of materials, including all types of metals, ceramics, plastics, glass, and wood. Whether it’s intricate details on small components or bold, large-scale markings, no task is too challenging for our advanced technology. With precise control and versatility, we can customize designs to meet your exact specifications, ensuring that every project—no matter the size or complexity—is executed with precision and quality.

Keel deploys advanced waterjet cutting technology to produce precision prototypes and detailed designs. We can custom cut to +\- 0.005 inches on designs ranging from one square inch to more than 10,000 square inches in nearly any material.

Machining

From standard components to the most intricate and complex parts, Keel has both the talent and the advanced tools necessary to transform your toughest machining challenges into practical, working realities. Whether it’s high-precision structures, complex geometries, or custom fabrication, our team excels at delivering solutions that meet the most demanding specifications, ensuring precision, reliability, and performance in every project.

CNC Milling

Our state-of-the-art CNC mills and skilled technicians ensure that every part is crafted to your exact specifications. Many of our milling machines accommodate parts with sizes larger than 96 inches x 96 inches. One of our largest capabilities is our 5-axis double column machining center with a maximum capacity of 80 inches x 148 inches x 394 inches. While two other 5-axis machines can handle up to 52 feet long.

CNC Turning

Our advanced CNC turning capabilities ensure tight tolerances, smooth finishes, and fast turnaround times. From prototypes to high-volume production, CNC turning provides the reliability and precision your project demands.

Our wide array of vertical and horizontal CNC turning centers boost capacities from 145 inches in diameter by 118 inches tall (perpendicular) to 35 inches in diameter by 120 inches long (horizontal).

Grinding

We offer both horizontal and vertical grinding services. Keel is a premier source for ID/OD grinding; we can handle parts up to 15 inches in diameter and 72 inches between centers while holding precise tolerances to 0.0005 inches over the entire length of the part. Our large-diameter vertical equipment provides close-tolerance, fine-finish ID/OD grinding up to 60 inches in diameter.

Laser Cutting/Marking

Precision only a laser can do. We have the capability to mark virtually any design onto a wide range of materials, including all types of metals, ceramics, plastics, glass, and wood. Whether it’s intricate details on small components or bold, large-scale markings, no task is too challenging for our advanced technology. With precise control and versatility, we can customize designs to meet your exact specifications, ensuring that every project—no matter the size or complexity—is executed with precision and quality.

Waterjet Cutting

Keel deploys advanced waterjet cutting technology to produce precision prototypes and detailed designs. We can custom cut to +\- 0.005 inches on designs ranging from one square inch to more than 10,000 square inches in nearly any material.

Our sophisticated equipment delivers unrivaled results.

We have a maximum capacity of:

6 1/2′ – Z, 14′ – Y, 39′ – Z dual column, 5-axis, high-speed machining center.

Vertical, 5-axis, Precision Floor Mill 52′ – X, 13′ – Y, 6′ – Z.

We are able to handle capacities up to:

Vertical – 145 inches in diameter by 118 inches tall

Horizontal – 35 inches in diameter to 120 inches long

Keel is a premier source for ID/OD grinding. Our large-diameter vertical equipment provides close-tolerance, fine finish ID/OD grinding, up to 60 inches in diameter.

Insights

View All

Keel Continues to Invest in Defense Production Capacity with $22 Million Midwest Equipment Purchase and Key Leadership Additions

Keel expanding Charleston County operations

Seapower Magazine: Keel: A Purpose-Built Company

Corporate Responsibility

We are committed to upholding the highest standards of safety, fairness and integrity.

At Keel, we protect and support our workforce, communities and customers by investing in those we care about. We believe the most important thing we build is a better, safer future for all.

CAREERS

Interested in joining forces? Explore Keel’s career opportunities