Maritime Defense

From shipboard systems to amphibious landing craft, we proudly provide expert manufacturing services for Maritime Defense.

Precision engineering for shipbuilding, defense components, and more.

We offer advanced manufacturing solutions for Maritime Defense, including landing craft, service life extension programs, shipboard systems, torpedo components, missile defense, and sonar systems. Our expertise ensures that every project meets the highest standards of precision and reliability. Partnering with KEEL means working with a team dedicated to delivering innovative, dependable solutions, ensuring flawless execution for your mission-critical maritime projects from start to finish.

What We Do

Whether it’s extending the life of aging vessels or incorporating the latest technological advancements, our team ensures that your ships are equipped to meet current and future demands, all while maintaining the highest standards of quality and safety.

Capabilities

- Shipbuilding

- Service Life Extension Programs

- Refurbishment

By combining the latest technologies with our specialized expertise, our assembly and outfitting capabilities make sure your ship is ready to perform in the most demanding conditions. From advanced hull fabrication to the installation of a wide-range of complex systems, our expert craftsmanship, stringent quality control, and adherence to military specifications give you the peace of mind to know it’s been done right.

Capabilities

- Shipboard Systems

- Missile Defense Components

- Radar Defense Assemblies

- Precision Machining

Our Integration and Testing capabilities ensure that all components work seamlessly together, with thorough testing to meet the highest standards of performance and reliability. Our approach includes rigorous quality control measures and continuous monitoring throughout the integration process, ensuring that each component interacts flawlessly with others.

Capabilities

- Secure Production and Assembly Facilities

- Integration and Testing Capabilities

While we routinely work in high-volume production, KEEL was custom-built for secure short-run and custom manufacturing projects. So, when your program needs special tooling and machining, but the order quantity makes your suppliers wince, it’s time to call KEEL.

Capabilities

- Special Tooling and Machining

- Short-Run and Custom Manufacturing

Shipbuilding & Repair

Ensure your fleet stands the test of time.

Whether it’s extending the life of aging vessels or incorporating the latest technological advancements, our team ensures that your ships are equipped to meet current and future demands, all while maintaining the highest standards of quality and safety.

Capabilities

Shipbuilding

Service Life Extension Programs

Refurbishment

Assembly & Outfitting

We ensure your naval vessels are mission-ready.

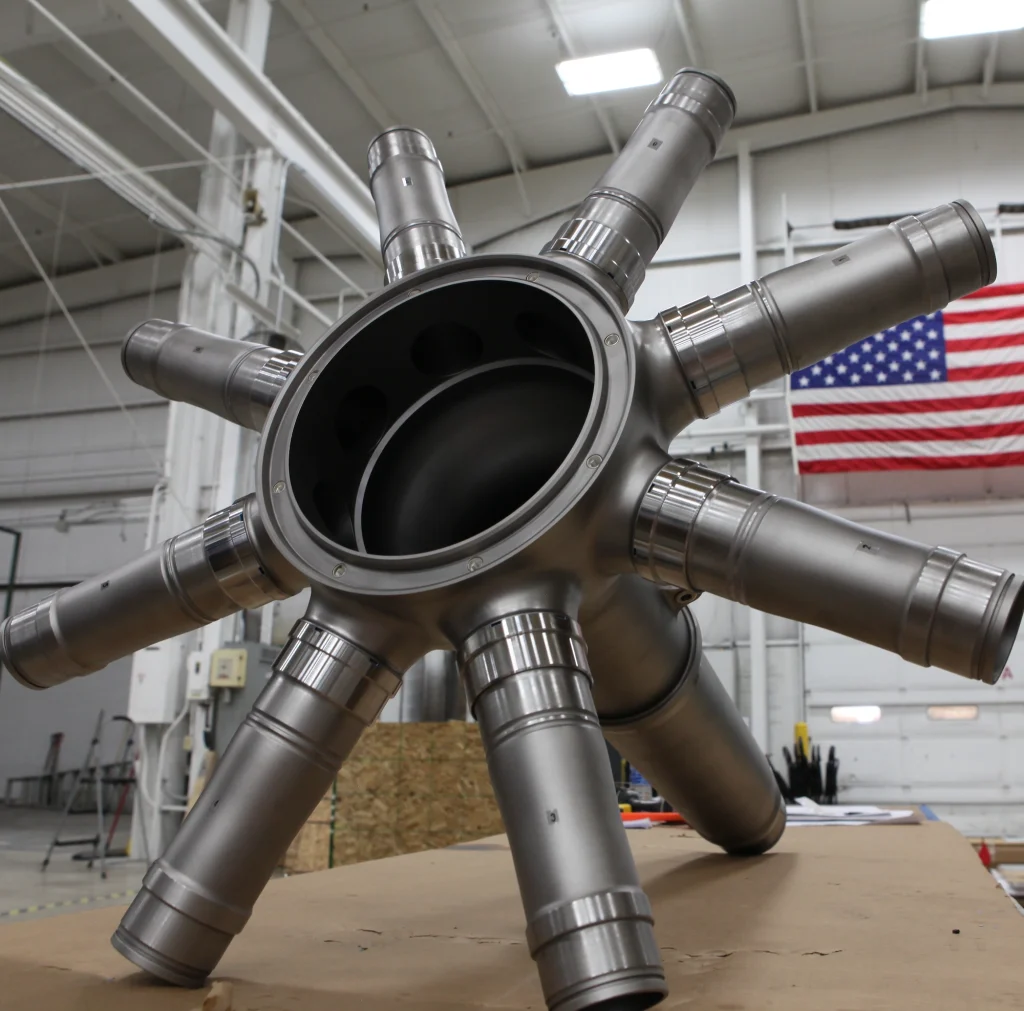

By combining the latest technologies with our specialized expertise, our assembly and outfitting capabilities make sure your ship is ready to perform in the most demanding conditions. From advanced hull fabrication to the installation of a wide-range of complex systems, our expert craftsmanship, stringent quality control, and adherence to military specifications give you the peace of mind to know it’s been done right.

Capabilities

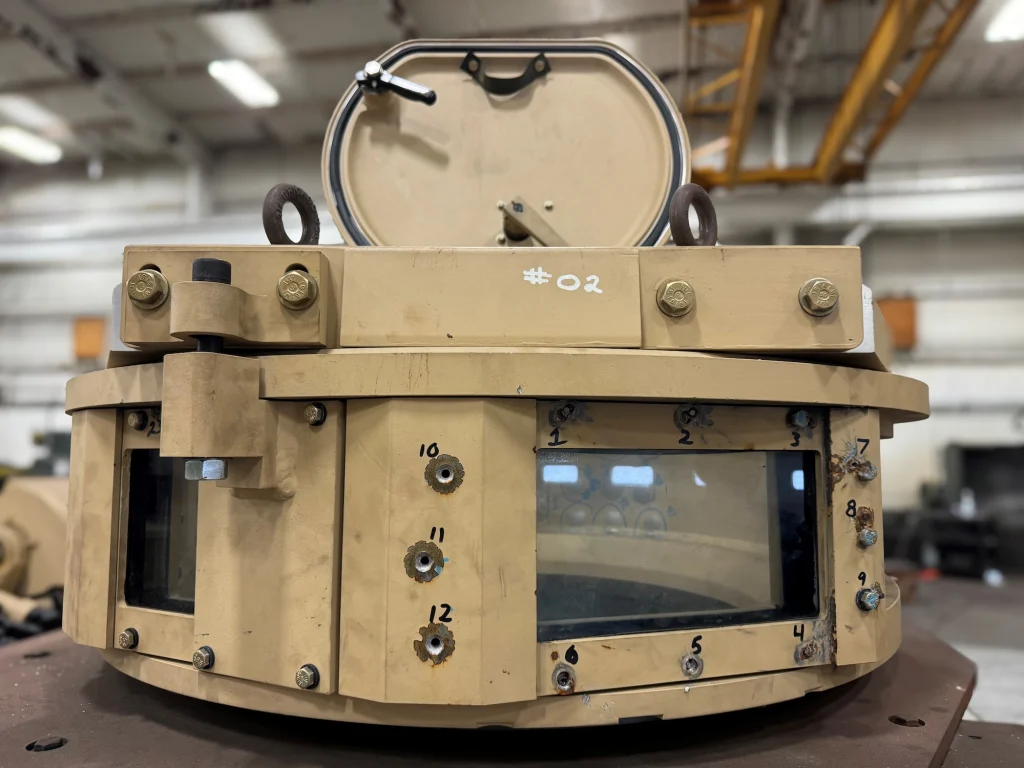

Shipboard Systems

Missile Defense Components

Radar Defense Assemblies

Precision Machining

Integration & Testing

A job well done. Guaranteed.

Our Integration and Testing capabilities ensure that all components work seamlessly together, with thorough testing to meet the highest standards of performance and reliability. Our approach includes rigorous quality control measures and continuous monitoring throughout the integration process, ensuring that each component interacts flawlessly with others.

Capabilities

Secure Production and Assembly Facilities

Integration and Testing Capabilities

Custom Production

Unique solutions for unique situations.

While we routinely work in high-volume production, KEEL was custom-built for secure short-run and custom manufacturing projects. So, when your program needs special tooling and machining, but the order quantity makes your suppliers wince, it’s time to call KEEL.

Capabilities

Special Tooling and Machining

Short-Run and Custom Manufacturing

Classified Functionality

We keep your information confidential.

We follow ITAR and NNPI guidelines and are working towards CMMC compliance once published. With secure facilities and a highly trained team, KEEL provides production security for even the most sensitive projects.

MARKETS

Looking for land-based systems? Click here to go to our Land, Surveillance & Launch page.

Insights

View All

Seapower Magazine: Keel: A Purpose-Built Company

Breaking Defense: Navy contractor KEEL to open new $70M facilities for submarine fabrication